In the area of modern structure, the choice of concrete admixtures straight influences the top quality and cost of the task. This brief article will absolutely concentrate on 2 vital admixtures – concrete lathering representative and defoamer, and contrast them from the viewpoints of feature, functions, application scenarios, and more to aid you in making an added informed selection.

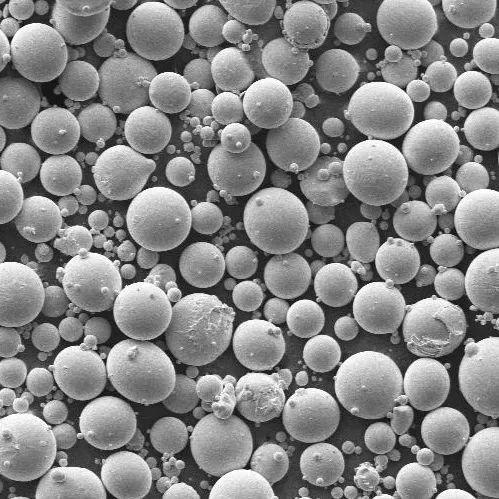

(Concrete foaming agent)

Product Fundamentals

1. Concrete foaming agent.Concrete lathering agent is a surfactant that reduces the surface tension of liquid and produces a huge amount of attire and steady foam under mechanical mixing. These foams are uniformly distributed in the concrete, developing a permeable structure, substantially decreasing the material thickness (300-800kg/ m FIVE) while maintaining a specific strength (compressive stamina can reach 20MPa).

2. Defoaming representative.

Framework insulation: The floor covering heating insulation layer and roofing insulation board can decrease power intake by greater than 30%. Filling structure: filling passage spaces and constructing spaces, attaining both audio insulation and weight decrease impacts.Municipal style: lightweight concrete walkways and court bases to lower structure lots.Boost the area surface of concrete and lower honeycomb concerns.

Benefits comparison and selection tips

Advantages of foaming agents

Reduced price: The price per cubic meter of foamed concrete is 20-30% lower than traditional materials.Flexible construction: can be cast on site to adjust to complex shapes.Environmental protection and power saving: The closed-cell framework minimizes carbon discharges and adapts the trend of green buildings.

Advantages of defoamers

Strength warranty: reduce bubble problems and avoid “shoddy building.” Enhanced durability: Reduces leaks in the structure and extends the life of concrete by 5-10 years.Surface top quality optimization: ideal for commercial projects with high needs on appearance.

Just how to pick?

Structure insulation: The flooring heating insulation layer and roof covering insulation board can reduce power use by more than 30%.

Packing framework: filling passage rooms and developing voids, accomplishing both audio insulation and weight decrease results.

Area format: light-weight concrete walkways and court bases to lower foundation whole lots.

Conclusion

Although concrete lathering representatives and defoaming representatives have opposite features, they each have their irreplaceable worth in the building and construction area. When selecting, you require to take into consideration the job positioning, cost spending plan and technical needs, and consult a specialist team to optimize the material proportion when needed.

Vendor

TRUNNANO is a globally recognized manufacturer and supplier of compounds with more than 12 years of expertise in the highest quality nanomaterials and other chemicals. The company develops a variety of powder materials and chemicals. Provide OEM service. If you need high quality Concrete foaming agent, please feel free to contact us. You can click on the product to contact us. (sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us

Error: Contact form not found.