Tungsten(III) Oxide: The Unstable Blue-Grey Cousin

(tungsten iii oxide)

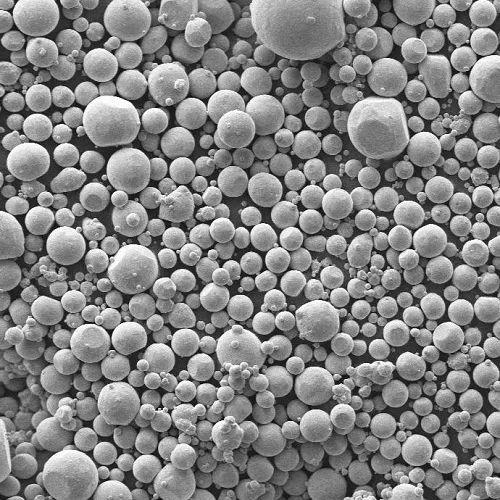

Formula: W₂O₃. Often non-stoichiometric, meaning slight deviations from the ideal ratio occur. Exists primarily as W₃O₈ or similar suboxides under ambient conditions.

Appearance: Typically manifests as a blue-grey or violet-black solid. This distinct color contrasts sharply with the yellow tungsten(VI) oxide (WO₃).

Properties: Highly unstable under atmospheric conditions. Prone to oxidation, readily converting back to higher oxides like WO₃ when exposed to air. This inherent instability makes handling difficult. Exhibits metallic conductivity due to partially filled d-orbitals in tungsten.

Synthesis: Cannot be made by direct combination of elements. Common methods involve controlled reduction of WO₃. Techniques include heating WO₃ with tungsten metal powder in vacuum or inert atmosphere, or carefully reducing WO₃ with hydrogen gas at specific temperatures. Requires precise conditions to avoid over-reduction to metal or under-reduction to WO₃.

Applications: Limited due to instability. Primary interest lies in catalysis research. Its unique electronic structure makes it a potential candidate for specific catalytic reactions, particularly where metallic conductivity combined with oxide character is beneficial. It may act as an intermediate in the reduction of WO₃ to tungsten metal powder. Also studied for its thermoelectric properties.

Challenges: Handling requires inert atmosphere techniques (glovebox, Schlenk line) to prevent oxidation. Its non-stoichiometric nature complicates precise characterization and property measurement. Synthesis reproducibility can be challenging.

(tungsten iii oxide)

Key Takeaway: Tungsten(III) oxide is a fascinating but temperamental material. Its instability restricts widespread use, but its unique properties, particularly conductivity and catalytic potential, drive niche research interest. Understanding its behavior requires careful synthesis and handling under oxygen-free conditions.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)