In this article, we will explore PCE Polycarboxylate Superplasticizer (PCPS) and its potential benefits for plastic manufacturing. The use of PCPS technology has gained significant attention due to its ability to improve the production efficiency and durability of products.

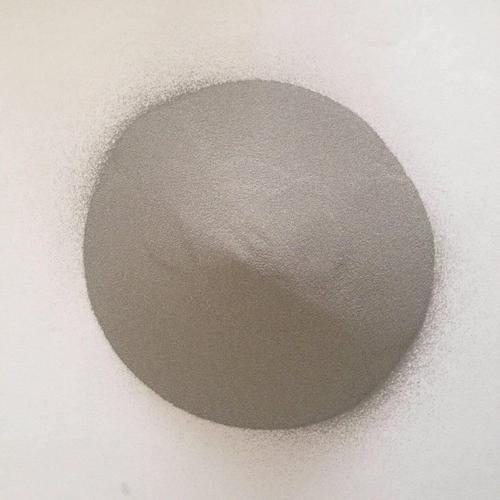

(pce polycarboxylate superplasticizer)

PCPS is a form of polymer that contains two different carboxyl groups (PKC). These PKCs serve as an intermediate step in the polymer chain, where they bond with water or other organic compounds. This process allows for the formation of polymers with high levels of strength,, and heat resistance.

PCPS technology can also be used to improve the quality of properties by controlling the size and distribution of the PKCs within the polymer chain. This helps to reduce the amount of waste produced during the manufacturing process and ensures that the final product meets the necessary standards.

Furthermore, PCPS can be used to produce composites, which are blends of plastic and materials that have similar mechanical and physical properties but differ in composition. This can help to reduce the cost of producing new products and improve their overall performance.

(pce polycarboxylate superplasticizer)

Overall, the use of PCPS technology has the potential to revolutionize the plastic manufacturing industry by improving the production efficiency, quality, and sustainability of products. However, it is important to consider the environmental impact of these technologies and to carefully evaluate their potential benefits and drawbacks before making a decision on whether to adopt them.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)