Concrete is a versatile material used extensively in construction due to its strength, durability, and ability to be customized with various additives and admixtures. These substances enhance the properties of concrete, addressing specific needs in different applications. While Portland cement is the primary component, other materials can be added to achieve desired characteristics.

(Beyond the Basics: Other Additives and Admixtures in Concrete (Duplicate))

### Air-entraining admixtures

Air-entraining admixtures introduce microscopic air bubbles into the concrete mix during the initial stages of hydration. This process improves the concrete’s resistance to freezing and thawing cycles, enhancing durability in cold climates. The air bubbles act as insulators, protecting the concrete from thermal stress that could lead to cracking.

### Superplasticizers

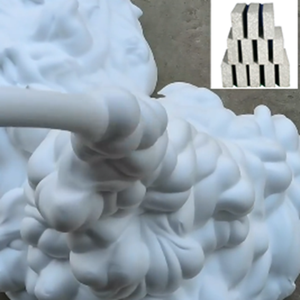

Superplasticizers reduce the water content required for the concrete mix without compromising workability or strength. They increase the flowability of the mix, making it easier to handle and pour. This reduces the amount of water needed, which in turn minimizes the amount of cement required. As a result, superplasticizers help in creating more sustainable concrete by reducing the overall carbon footprint.

### Fiber-reinforced concrete

To enhance the tensile strength and crack-resistance of concrete, fibers such as steel, glass, or synthetic polymers can be added. These fibers are dispersed throughout the concrete matrix, improving its ability to resist cracking under tensile stress. Fiber-reinforced concrete is particularly useful in areas prone to freeze-thaw cycles, where traditional concrete may crack over time.

### Color pigments

Color pigments are used to impart color to concrete, allowing for aesthetic customization. These pigments are added during the batching process, ensuring uniform color distribution throughout the concrete. They do not affect the structural properties of the concrete but provide an attractive finish suitable for sidewalks, driveways, and decorative architectural elements.

### Accelerators and retarders

These admixtures control the rate of hydration, either speeding up or slowing down the setting time of concrete. Accelerators are used when rapid hardening is necessary, such as in emergency repairs or during winter conditions when faster curing is advantageous. Retarders, on the other hand, are used when a longer working time is required, for example, in large pours or complex forms where precise timing is crucial.

### Water reducers

Water reducers decrease the amount of water needed for a given workability, leading to stronger, denser concrete. By reducing water content, they also minimize the formation of voids and weak spots, resulting in improved durability and performance.

### Rust inhibitors

In environments where corrosion is a concern, rust inhibitors are added to prevent the formation of rust in reinforcing steel. This protects the steel reinforcement from corrosion, extending the service life of the structure.

### Fire-resistant admixtures

These admixtures are designed to enhance the fire resistance of concrete. They incorporate materials that expand upon heating, creating a protective layer around the concrete that slows down the spread of fire.

### Eco-friendly admixtures

In recent years, there has been a growing trend towards using environmentally friendly admixtures. These include admixtures made from recycled materials, low-VOC (volatile organic compounds) products, and those that contribute to sustainable construction practices.

(Beyond the Basics: Other Additives and Admixtures in Concrete (Duplicate))

Incorporating these additives and admixtures into concrete formulations allows for customization tailored to specific project requirements, enhancing both the functional and aesthetic aspects of concrete structures.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)